Stacker or Mini Load Cranes

Designed for high-density storage environments, stacker cranes and mini-load systems provide fast, reliable movement of goods within automated racking systems. They can retrieve or store items with millimetre accuracy and integrate fully with your WMS to maintain real-time inventory visibility.

AGV / LGV'S

Our AGV and LGV solutions offer autonomous transport for pallets, totes, and materials throughout your facility. These vehicles use laser, magnetic, or vision-based navigation to move safely and precisely — minimising handling errors and improving efficiency.

Robotic Palletising Systems

Automate your end-of-line processes with precision-engineered robotic palletising systems. Our range of Fanuc robots handles a variety of load types and packaging formats, improving efficiency, safety, and consistency in pallet stacking operations. Each solution is tailored to your layout and throughput needs.

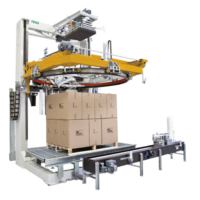

Stretch Wrapping Machines

Our advanced stretch wrapping machines deliver fast, secure, and consistent wrapping for pallets of all shapes and sizes. Designed for reliability and low maintenance, they ensure load stability while reducing film waste. PHS supplies and supports the full range of Tosa stretch wrapping systems.

Frequently Asked Questions

We provide a complete range of warehouse automation solutions, including Automated Guided Vehicles (AGVs), Laser Guided Vehicles (LGVs), stacker and mini-load cranes, robotic palletising systems, and stretch wrapping machines. Each solution is tailored to your site’s layout, throughput, and operational goals.

Yes. All our automation systems are designed for seamless integration with existing Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) software. This ensures real-time data sharing, smooth process coordination, and full visibility of your logistics operations.

Our team carries out detailed site surveys, system simulations, and ROI analysis to identify the most effective automation strategy for your business. We take into account your product types, workflow patterns, and expansion goals before designing a bespoke system.

Automation enhances performance across multiple industries, including logistics, manufacturing, retail, food and beverage, pharmaceuticals, and e-commerce. It helps increase speed, accuracy, and safety while reducing operational costs.

Yes. Our in-house engineers handle every stage of the process — from installation and commissioning to maintenance and service support. We also offer remote diagnostics and rapid-response assistance to minimise downtime.

Robotic palletising systems automate the stacking of products onto pallets, ensuring accurate, repeatable placement every time. This significantly boosts throughput, reduces manual handling, and lowers the risk of injury or product damage. Each system can be configured for your specific load types and packaging formats.

Automated stretch wrapping machines deliver consistent, secure wrapping for every pallet, improving load stability and reducing film waste. They enhance efficiency, safety, and reliability in dispatch areas, helping maintain high productivity levels. Our Tosa stretch wrapping machines are trusted worldwide for their precision and performance.