Automated Conveyor Systems for Material Handling & Packaging

Our conveyor systems are designed to meet the growing demands of modern production and distribution environments. Built for performance, safety, and durability, they efficiently move products of all shapes and weights, optimising workflow across packaging, palletising, and storage operations.

Whether you’re transporting cases, totes, or pallets, we deliver customised conveyor solutions that integrate seamlessly with your automation, robotics, and wrapping equipment to create a smooth, end-to-end material handling process.

Case/Tote Conveyors

Our case and tote conveyors are ideal for high-speed distribution and order fulfilment environments. These systems are designed for gentle product handling, with options for belt, roller, or modular chain conveyors that ensure quiet, reliable transport of cartons, trays, or totes.

We can incorporate accumulation, merging, and sortation functions to manage variable product flows efficiently, while minimising manual handling and line stoppages.

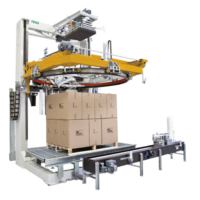

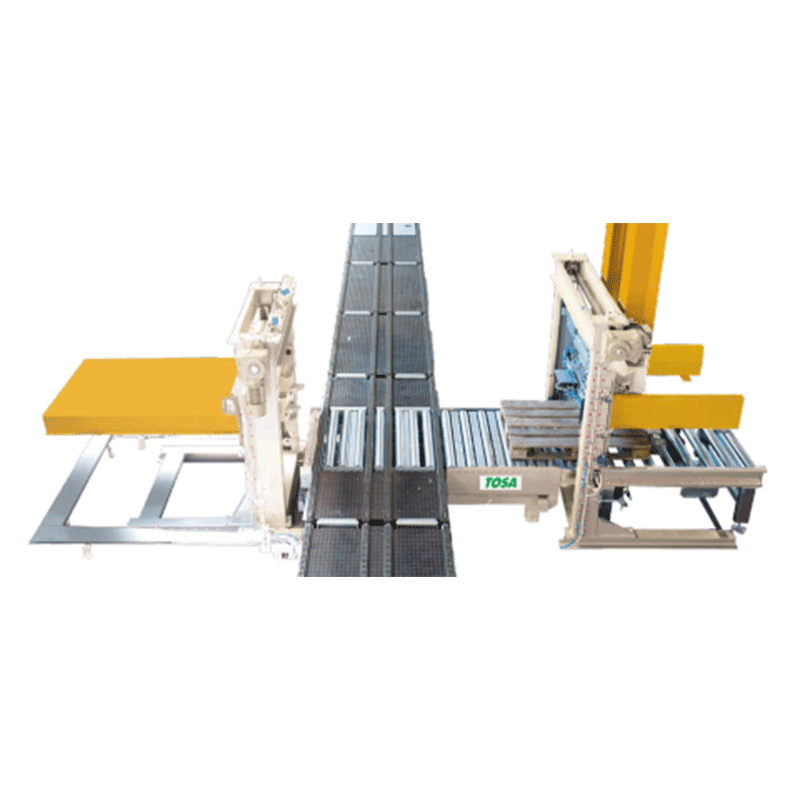

Pallet Handling Conveyors

Our pallet conveyors are engineered to move heavy or bulk loads safely and efficiently. Suitable for warehouse automation, palletising, and despatch zones, they can handle a wide range of pallet formats, including UK and Euro standards.

We provide roller and chain-driven designs with transfer tables, turntables, and shuttle systems, all integrated with your palletisers, wrappers, and warehouse control systems for complete process automation.

Frequently Asked Questions About Conveyor Systems

Belt, roller (gravity and motor-driven), modular plastic belt, chain, case/tote conveyors, pallet conveyors, spirals, incline/decline, turntables, merges/diverts and right-angle transfers.

Yes — PLC/SCADA integration plus WMS/MES/ERP links for routing, barcode/RFID, weigh/inspect and line interlocks.

Yes — zero-pressure accumulation, pop-up chain transfers, 90° diverts, merges, indexers and combiners configured to your throughput.

Systems are specified to your product and rate — from light totes and cases through to UK/Euro pallets. Share weights, dimensions and target throughput and we’ll size the equipment.

Guarding to standards, emergency pull-cords, light curtains, safe-torque-off drives and CE/UKCA documentation as required.

We offer full turnkey install, commissioning and operator training — with phased works or weekend changeovers to minimise downtime.

Yes — planned maintenance, breakdown support and spares for our systems and many third-party conveyors.