Tray Erectors

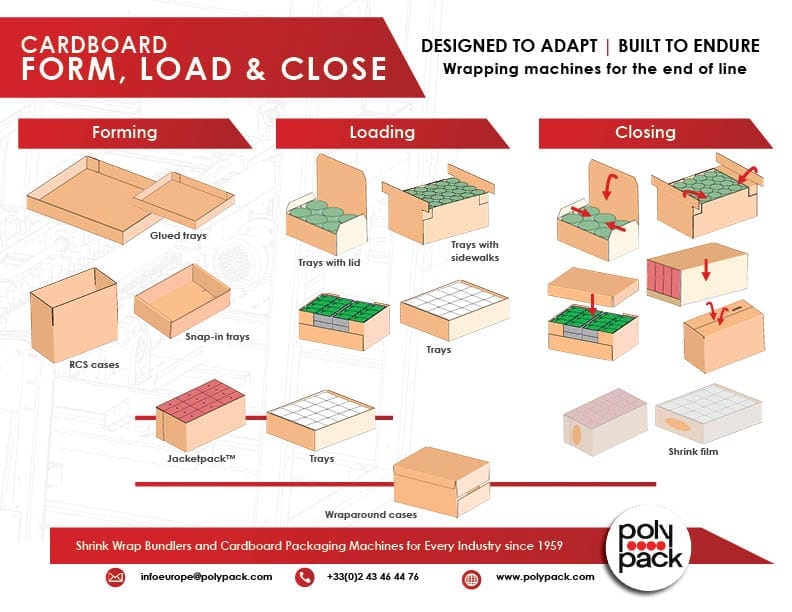

Tray Erectors automate the process of constructing trays from flat blanks, significantly streamlining production lines by eliminating manual assembly. By swiftly and accurately folding and securing the blanks into trays, they not only enhance the speed of packaging operations but also improve consistency and reliability across the board. Designed to cater to a variety of tray designs and sizes, Tray Erectors are versatile enough to meet the diverse needs of sectors such as food and beverage, electronics, pharmaceuticals, and agriculture.

Frequently Asked Questions About Tray Erectors

They handle common formats including display trays, open/closed trays, hood-and-tray (SRP), 4- and 6-corner glued trays, and wraparound trays in corrugated or solid board (model dependent).

Typical speeds are ~10–40 trays per minute with recipe-based changeovers. Each model supports a defined L×W×H range; we’ll match the machine to your blanks and speeds.

Hot-melt glue is standard for tray erection. Tape and hybrid sealing solutions are available where the application allows.

Pre-cut/die-cut blanks in corrugated or cartonboard. We’ll confirm flute/grade, flap geometry and glue pattern during FAT to guarantee square, rigid trays.

Tool-less or minimal-tool adjustments with saved recipes; automatic guides and digital indicators are available to reduce changeover time and variation.

Yes — full integration with case/pack loaders, shrink or sleeve wrappers, printers/labelers, vision checks, conveyors and end-of-line palletising/ wrapping.

Compact footprints with 230/400V (model dependent) and 6 bar clean, dry air. Machines ship with CE/UKCA guarding, interlocks and e-stops as standard.

Yes — turnkey install, commissioning, operator training, maintenance and spares across GB and IE.